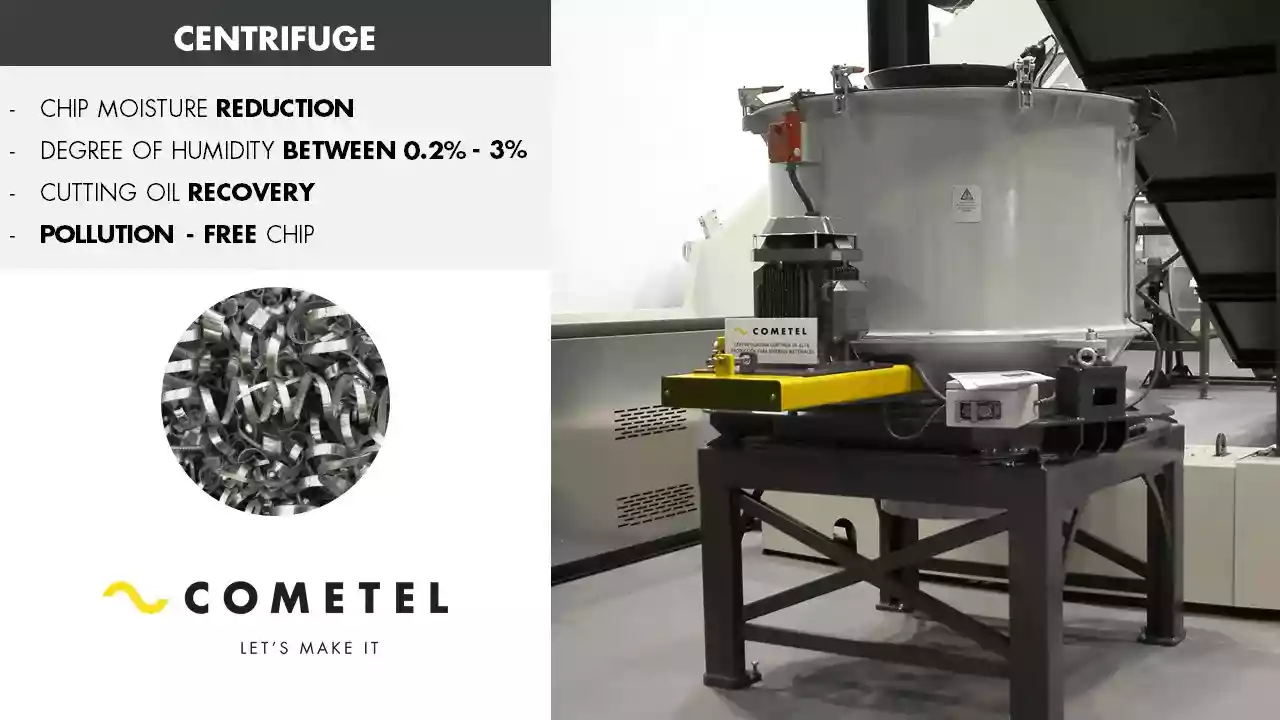

COMETEL CENTRIFUGE

The centrifuge is one of the most used pieces of equipment if your main objective is to get the most out of the metal chip obtained in the machining processes.

But what exactly does the centrifuge do? What is the process?

Mainly, it is responsible for removing the coolant that remains attached to the chip in the manufacturing process. The process is simple: the short chip arrives at the centrifuge with a significant degree of humidity acquired by the coolants used. Later, and thanks to the centrifugal force, the liquids (oil or coolant) are separated from the solids (chips). Finally the liquid is stored for possible reuse and the chip passes with a much lower degree of humidity.

Cometel centrifuges are characterized by the wide variety of advantages they offer when dealing with metal chips. These advantages are:

- A REDUCTION IN THE MOISTURE OF THE CHIP

- REACHING A DEGREE OF HUMIDITY BETWEEN 0.2% AND 3%

- THE RECOVERY OF CUTTING OILS

- THE OBTAINING OF POLLUTION-FREE CHIPS

The result is a highly efficient device for recovering solids that either cannot be separated efficiently or need to be recovered in much greater quantities.

If you want to know more about this type of equipment, its benefits and the models of centrifuges that we offer, you can obtain more information in our metal chip section.

Or you can also take a lok at our case study where we show how we replaced a centrifuge that worked in circles for one that works continuously.

Email: salesrecycling@cometel.net

Tlf: +34 943 74 30 50