STORAGE, TRANSPORT AND SEPARATION PRIOR TO THE FURNACE

The end of the year is approaching and we couldn't do it in a better way: with new projects that are already on their way to our clients' facilities.

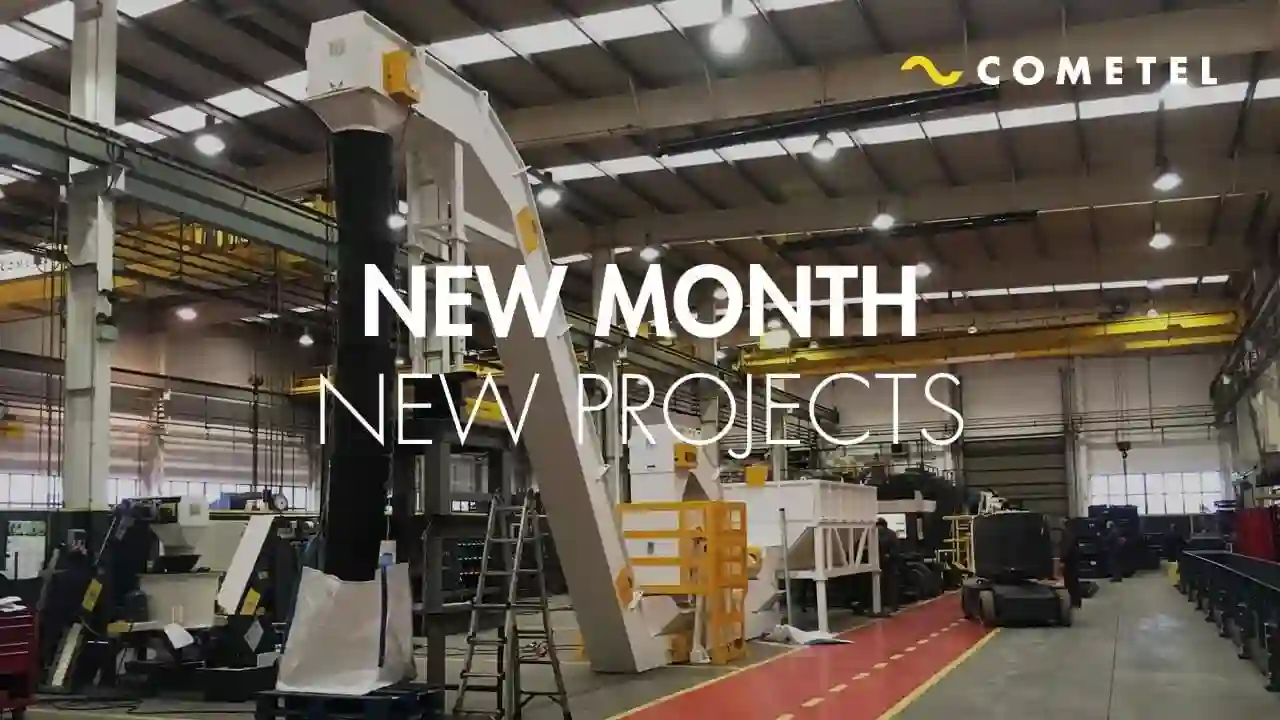

We have recently completed this new project and is in the process of being delivered. It consists of the storage, treatment and transport of aluminium chips that contain ferrous particles.

Our client wanted a solution that would allow them the storage of a large amount of material at the beginning of the treatment and thus achieve a fully automated process, without the need for human manipulation.

For this, our team designed a complete installation that consists of a large 7m³ spindle hopper, a loading conveyor, a magnetic drum and a long swan neck infeed conveyor for loading the chips into the furnace.

The main function of the hopper is the storage of the chip and to make the loading to the conveyor in an automatic way.

On the other hand, in the next phase, the first conveyor will raise the chip until it is discharged into the magnetic drum. With the drum we separate the aluminium chip from all the ferrous particles it contains, obtaining a clean aluminium chip, free of contamination.

Finally, the last conveyor will raise the chip until it is discharged into the furnace where it will be melted.

Email: salesrecycling@cometel.net

Tlf: +34 943 74 30 50